Organosilicones are a large class of compounds that contain a silicon-carbon bond (Si-C) and have at least one organic group directly attached to the silicon atom. These compounds usually include silicone, whose main chain structure is a stable silicon-oxygen (Si-O) bond and whose side chains consist of various organic groups. Silicone materials are widely used in many fields such as industry, construction, automotive, aerospace, electronics, chemical, and pharmaceuticals because of their unique properties, such as temperature resistance, weather resistance, electrical insulation, chemical stability, surface activity, mechanical properties, and physiological inertness.

The historical development of silicones can be traced back to the chemical explorations of the late 19th and early 20th centuries, and its industrialization has taken a leap from laboratory research to global scale production. The following are the key stages of development and important milestones:

In 1863, French chemists C. Friedel and J. M. Crafts synthesized tetraethylsilane, a compound containing silicon-carbon bonds, for the first time through the reaction of silicon tetrachloride with diethylzinc, marking the starting point of organosilicon chemistry.

In 1901, British chemist F. S. Kipping successfully prepared methylchlorosilane and phenylchlorosilane by reacting with tetrachlorosilane using Grignard's reagent and further hydrolyzed and condensed to obtain the first organosilicon polymer, polydiphenylsiloxane, laying the theoretical foundation of organosilicon chemistry.The initial formation of the concept of organic silicon

Kipping's systematic studies revealed chemical differences between silicon and carbon, such as the ability of silicon's d-orbitals to participate in bonding, and the stability of silicon-oxygen bonds. He misidentified silicone polymers as "silicones" containing ketone groups, a name that is still used today.

In the 1930s, Dow Chemical and Corning cooperated in the research and development of silicone materials and established Dow Corning in 1943, focusing on the industrialized production of silicone. Its technology is highly confidential, and it has become the global leader in the field of silicone.

In 1940, Rochow invented the "direct method" to synthesize hydrocarbon-based chlorosilanes (direct reaction between silica powder and chloromethane), which replaced the Kihei's Gram's reagent method, dramatically reduced the production cost, and became the core technology for the industrialization of organosilicones.

During World War II, silicone was used in military applications for its high temperature resistance and insulating properties, such as insulating grease for aircraft ignition systems and rocket seals. After the war, the civilian market expanded rapidly, such as silicone rubber used in the Apollo moon landing program of the astronaut suit sole

Structural unit and functional design: Diversified products such as silicone oil, silicone rubber, and silicone resin are developed through the combination of M (monofunctional), D (difunctional), and T (trifunctional) units to satisfy the needs of high temperature resistance (-120°C to 500°C) and corrosion resistance.

Modern application scenarios: from building sealants and automotive parts to medical implants (such as artificial hearts) and electronics packaging, silicone has become an "industrial vitamin", and the global market size is expected to exceed 60 billion dollars in 2025.

The history of silicones is not only a history of advances in materials science, but also a microcosm of mankind's efforts to solve engineering challenges through chemical innovation. Its journey from laboratory to industrialization reflects the dual drive of basic research and market demand.

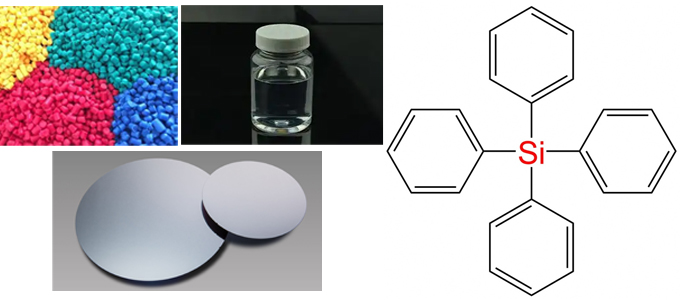

Classification of silicone silicone is mainly divided into four categories: silicone oil, silicone rubber, silicone resin and silane coupling agent.

Silicone oil (polysiloxane) is a class of synthetic polymer compounds with silicone-oxygen bond (Si-O) as the main chain and organic groups connected to the side chain, has unique physicochemical properties and is widely used in the fields of daily chemicals, industry, and medical treatment.

The main applications of silicone oils and their derivatives are:

Film release agents, shock absorbing oils, dielectric oils, hydraulic oils, heat transfer oils, diffusion pump oils, defoamers, lubricants, hydrophobicity agents, paint additives, polishing agents, additives for cosmetics and daily necessities, surfactants, particle and fiber treatments, silicone grease, flocculants.

Silicone rubber is a kind of polymer elastic material with silicone-oxygen bond (Si-O) as the main chain and organic groups (e.g., methyl, vinyl, phenyl, etc.) connected to the side chain, which has the stability of inorganic substances and the flexibility of organic substances.

Silicone rubber is divided into Room Temperature Vulcanized Silicone Rubber (RTV Silicone Rubber) and High Temperature Vulcanized Silicone Rubber (HTVSilicone Rubber).

RTVSilicone Rubber are mainly used in: sealants, adhesives, conformal coatings, gaskets, foam rubber, molded parts, encapsulation materials, electrical insulation, glass assembly, medical implants, surgical aids, and mold making materials;

HTVSilicone Rubber are mainly used in: pipes and hoses, strips, wire and cable insulation, surgical aids, flame-retardant rubber parts, penetrating seals, molded parts, embossing rollers, automotive ignition cables and spark plug covers, extruded parts, medical implants, laminates, electrically conductive rubbers, fiber coatings, foam rubbers.

Silicone resin is a highly cross-linked thermosetting polysiloxane polymer with Si-O-Si as the main chain and organic groups (e.g., methyl, phenyl, etc.) attached to the side chains, which has both the stability of inorganic materials and the flexibility of organic materials.

The main applications of silicone are:

Varnishes, insulating varnishes, molding compounds, protective coatings, encapsulating materials, bonding coatings, pressure sensitive adhesives, laminating resins, release agents, adhesives, masonry water repellents.

Silane coupling agent is a class of low molecular organosilicon compounds with special structure, whose general formula is RSiX₃, in which R represents the active functional group reacting with organic matter (such as amino, epoxy, vinyl, etc.), and X represents hydrolyzable group (such as methoxy, ethoxy, etc.). These compounds can establish "molecular bridges" between inorganic materials and organic polymers through chemical bonding or physical adsorption, significantly improving the interfacial bonding, mechanical properties and durability of composites.

Silane coupling agents are mainly used in paints, plastic and rubber processing, and adhesives.

Contact: Tony Li

Phone: +86-13263299644

Tel: +86-13263299644

Email: sales@ecoviaet.com

Add: No 3 Youyi Road,Tangshan,Huantai,Zibo,China

We chat