Product Description:

Silicone Rubber for Molding (Fumed Silica): Ensuring Safety and Performance

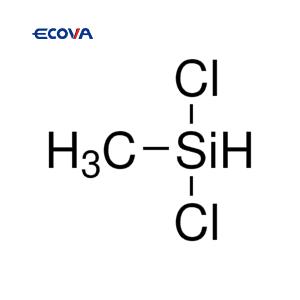

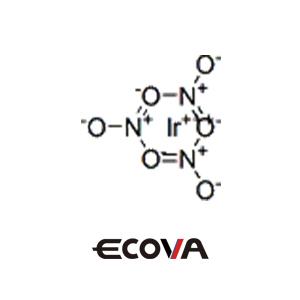

Our specialized silicone rubber compounds, formulated with high-quality fumed silica, are specifically designed for molding components used in medical equipment and food-grade products. Fumed silica reinforcement enhances the mechanical properties and purity of the silicone, making it an ideal choice for applications where biocompatibility, hygiene, and reliability are paramount.

These materials are manufactured to meet stringent industry standards, ensuring the safety and performance required for sensitive applications.

Key Applications in Medical and Food Industries

Our fumed silica-based silicone rubber is ideal for molding a wide range of parts, including:

Medical Devices: Seals, gaskets, tubing connectors, diaphragms, and other components requiring biocompatibility and sterilization capabilities.

Food Processing Equipment: Seals, O-rings, conveyor belts, and other parts that come into direct contact with food, ensuring food safety and hygiene.

Laboratory Equipment: Stoppers, seals, and tubing requiring chemical inertness and purity.

Wearable Medical Devices: Soft and flexible components for patient comfort and safety.

Infant Care Products: Nipples, valves, and other components requiring non-toxicity and durability.

Our Medical & Food Grade Silicone Rubber Product Range

We offer a selection of silicone rubber compounds formulated with fumed silica, each tailored to meet specific performance requirements for molding applications:

| Index | ES-9130 | ES-9140 | ES-9150 | ES-9160 | ES-9170 |

| Appearance | Milky-white, transparent, no mechanical impurities. |

| Hardness Shore A | 30 ±3 | 40 ±3 | 50 ±3 | 60 ±3 | 70 ±3 |

| Tensile Strength, (MPa)≥ | 6 | 6.5 | 8 | 8 | 7.5 |

| Elongation At Breakage,%≥ | 600 | 400 | 350 | 300 | 220 |

| Tensile Set At Break, % ≤ | 8 |

| Tear Strength, (kN/m)≥ | 15 | 19 | 22 | 22 | 20 |

Key Benefits of Our Fumed Silica Silicone Rubber for Molding

High Purity and Biocompatibility: Ideal for medical and food contact applications.

Enhanced Mechanical Strength: Fumed silica reinforcement provides excellent tensile and tear strength.

Wide Hardness Range: Offering flexibility from soft to hard molded components.

Excellent Elasticity and Flexibility: Ensuring durability and performance in demanding applications.

Temperature Resistance: Maintaining properties across a broad temperature range.

Chemical Inertness: Resistant to many chemicals and sterilization methods.

Low Compression Set: Ensures long-term sealing performance.

Customizable Formulations: Tailored to meet specific application requirements and regulatory standards.

Regulatory Compliance

Our medical and food-grade silicone rubber compounds are manufactured with strict adherence to relevant industry regulations and standards. Please contact us for specific compliance information regarding our product grades.

Technical Expertise and Custom Solutions

Our experienced technical team is available to assist you in selecting the optimal silicone rubber compound for your molding needs. We offer comprehensive technical support and can develop custom formulations to meet your unique application and regulatory requirements.

Contact us today to discuss your project and request a quote.

English

English