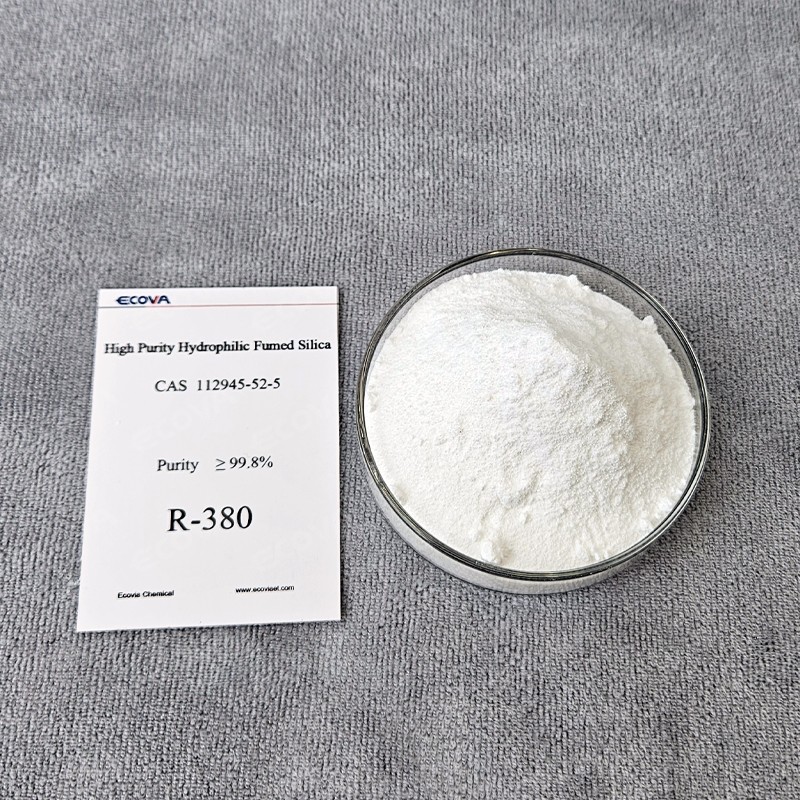

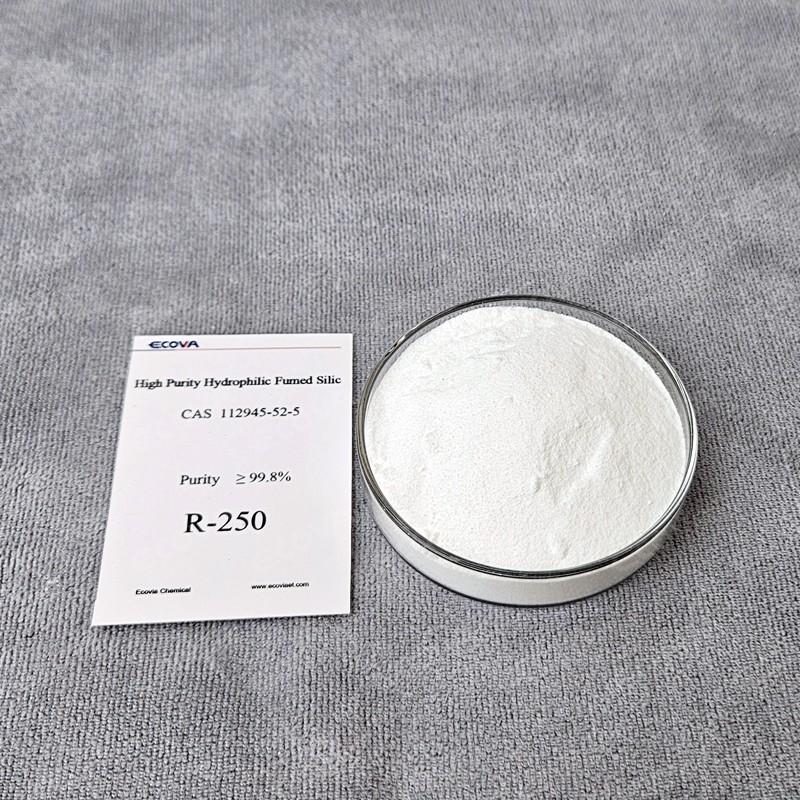

Product Overview

Our Hydrophilic Fumed Silica is a high-purity, synthetic, amorphous silicon dioxide (SiO2) powder produced via a high-temperature flame hydrolysis process. This untreated fumed silica is characterized by its extremely small particle size ( nanoscale), large specific surface area (50~400m²/g), and a three-dimensional chain-like structure. These unique properties make it a versatile additive used in a wide range of industries to improve product performance.

Hydrophilic fumed silica readily adsorbs water and can form hydrogen bonds, making it an effective rheology modifier, thickener, anti-settling agent, and reinforcing agent in various liquid and powder systems. Our grades offer different specific surface areas to cater to diverse application requirements.

Technical Specifications

The following table details the typical properties of our Hydrophilic Fumed Silica grades:

| Item | SO₂ content wt% | loss on drying 2h@105℃ | 4% Suspension PH value | Specifi Surface Area (BET) ㎡/g |

| R-150 | 99.80% | ≤ 2.5 | 3.8 ~ 4.5 | 130-170 |

| R-200 | 180~220 | |||

| R-250 | 226 ~ 275 | |||

| R-300 | 276 ~ 335 | |||

| R-380 | 336~405 |

Note: The data provided are typical values and not intended as product specifications. Specifications are available upon request.

Key Properties & Benefits

Excellent Thickening & Viscosity Control: Effectively increases viscosity and provides thixotropic behavior in liquid systems.

Rheology Modification: Optimizes flow characteristics, preventing sagging in coatings and providing desired texture.

Anti-Settling & Anti-Sagging: Improves the suspension of pigments and fillers, preventing settling during storage and sagging during application.

Reinforcement: Enhances mechanical properties such as tensile strength, tear strength, and hardness in elastomers like silicone rubber.

Free-Flow & Anti-Caking Agent: Improves the flowability and prevents caking of powders in various applications.

High Purity: Minimal impurities, ensuring consistent performance and suitability for sensitive applications.

Large Specific Surface Area: Provides a high level of interaction with the surrounding medium.

Improved Dispersibility: Though hydrophilic, it can be effectively dispersed with appropriate shear.

Applications of Hydrophilic Fumed Silica

Our Hydrophilic Fumed Silica is widely used across various industries, including:

Paints and Coatings: For rheology control, anti-sagging, anti-settling of pigments, and improved coating stability.

Adhesives and Sealants: To control viscosity, provide thixotropy, enhance bond strength, and improve anti-sag properties.

Silicone Rubber (HTV & RTV): As a primary reinforcing filler to improve mechanical properties.

Unsaturated Polyester Resins, Laminating Resins & Gel Coats: For thickening, thixotropy, and preventing sag.

Printing Inks: To adjust viscosity and improve print definition.

Composites: As a functional filler to enhance mechanical strength and modify rheology.

Cosmetics and Personal Care Products: As a thickener in creams and lotions, a suspending agent, and a free-flow agent in powders.

Pharmaceuticals: As an excipient, glidant, and tablet disintegrant (for appropriate pharmaceutical grades).

Powder Coatings: To improve fluidization and prevent caking.

Greases: As a thickening agent.

The suitability of a specific grade depends on the application and desired performance. Please contact us for recommendations.

Handling & Storage

Hydrophilic Fumed Silica is a very fine, lightweight powder and can generate dust during handling. It is recommended to use appropriate personal protective equipment (PPE), such as dust masks or respirators, safety goggles, and gloves, to avoid inhalation and contact with eyes and skin. Ensure adequate ventilation in the work area.

Store in a dry, cool, and well-ventilated place, away from volatile substances, as fumed silica can adsorb them. Keep containers tightly closed to prevent moisture absorption, which can affect its performance.

For detailed safety information, please refer to the Material Safety Data Sheet (MSDS) for the specific grade.

English

English

![Octamethylcyclotetrasiloxane(D4) CAS 556-67-2 [(CH₃)₂SiO]₄](/Uploads/pro/octamethylcyclotetrasiloxane-556-67-2.127.1.jpg)